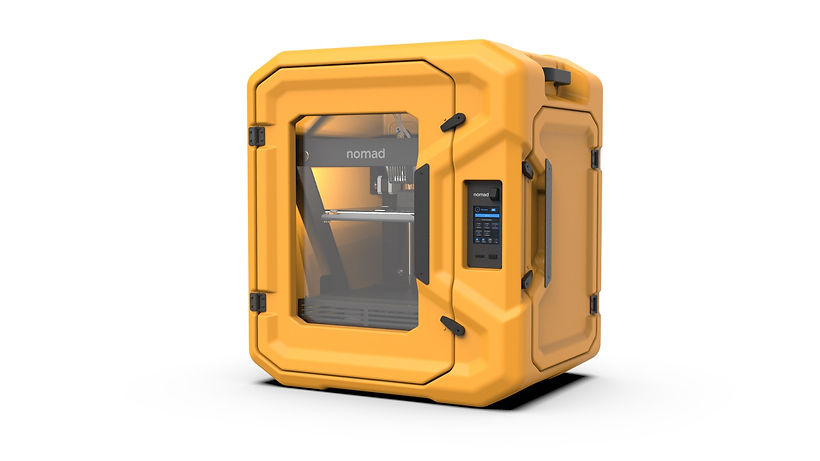

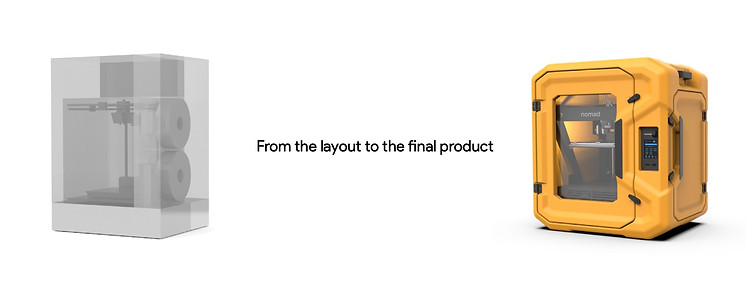

Nomad is a 3D printer for NGOs used in emergency situations directly in the field, for Maintenance and Repair Operations.

For NGOs, supply chain is often problematic.

Nomad reduces the cost and time needed in humanitarian relief by instantly creating supplies required in the field.

Nomad is a nomadic 3D printer that travels on NGO vehicles to reach emergency sites.

Loaded on pickups, trucks and airplanes, it travels from site to site when needed.

It is to be located in the field office, the on-site logistics centre of the NGO. It can be set up in local buildings, in prefabricated buildings or in tents.

Shell

The outer shell is a single component, made of HDPE, and produced using rotational moulding to ensure high performance and lower costs.

The two layers of material reinforce the component and guarantee protection to the delicate technology within.

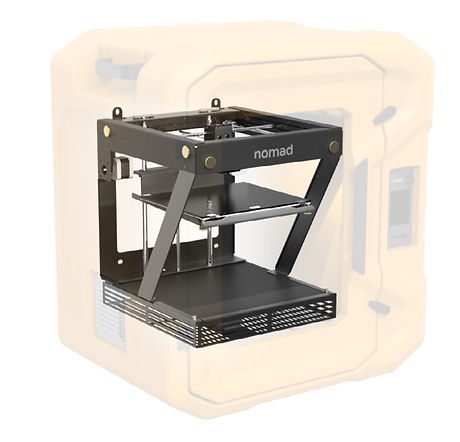

Frame

The printing technology is contained within a sheet metal frame.

The frame is connected to the shell by four vibration dampening mounts to further protect the technology during transport.

Furthermore, the steel frame is designed to minimise material wastage during production, and ensures the product remain light and easy to reach when repairs are necessary.

Transport

Large upper handles are useful when loading and unloading from vehicles.

Lower Indents in the shell act as simple but effective lower handles.

Maintenance

Finally, a maintenance kit remains with the printer at all times, in the compartment under the electronics.

It guarantees that all minor repair or calibration operations can be done on site.

Designed in collaboration with

Filippo Viciani, Leonardo Giovanelli,

Pedro Augusto Pereira Basile

at Politecnico di Milano, 2020

jpeg_edited.jpg)